|

|

0.91 |

x 1 | |

|

|

150 mAh battery |

x 1 |

|

KiCad 9.0 |

|

|

MounRiver StudioMounRiver

|

|

|

fusion360 |

Light meter for analog cameras [CH32V006F8P6 + TSL2591]

Light meter for analog cameras [CH32V006F8P6 + TSL2591]

In this article, I show you how I built my own light meter for (mainly) analogue cameras. The light meter is based on the CH32V006K8U6 microcontroller and the TSL2591 light meter chip. The device, based on the intensity of the incident light, suggests exposure parameters based on the fixed parameters that are given to the device. It works similarly to digital light meters on the market, but it is cheaper and fully DIY, so other people can replicate it. I already built the electronics and developed parts of the code in my previous project, and in this project, I show the PCB I designed and the program I wrote for the microcontroller.

Introduction

So, I have already laid the foundations of this project when I did my demo video for the CH32V006K8U6 chip with the TSL2591 light sensor. I had already programmed most of the functions back then, and I also came up with a circuit diagram.

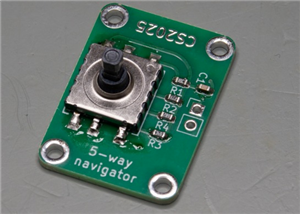

But, there was more to be done. I had to design a whole new circuit that incorporates more than just the chip and the light sensor. The circuit of this project operates on a lithium battery, so a charging circuit and a USB connector were added to the circuit. There’s also an OLED display that shows all the information regarding the measured light and the suggested camera parameters. Then, the user must somehow be able to set the parameters to calculate the exposure variables. The code allows the user to operate in aperture-priority and shutter-priority modes. But, apart from the measured light, the formulas need, for example, the ISO value set on the camera. All the necessary parameters can be set by a nice 3-way navigation button. The navigation button might be familiar to those ’90s kids who had MP3 players back then. This is a similar button that was in those MP3 players. The function of the switch is also somewhat similar: one can go up and down by tilting the button, plus by pressing the button in, a third behaviour can be assigned to the action. The program is written accordingly. The button is used for navigating in a menu where we can set different parameters.

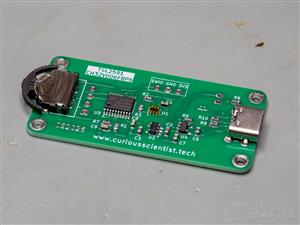

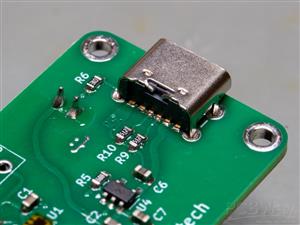

The device, as I mentioned earlier, is operated by a battery. I chose a tiny, 150 mAh lithium battery for this project. By some back-of-the-envelope calculations and some rudimentary measurements, the device can operate continuously for 12+ hours (considering a roughly 20% margin). The device is programmed in a way that it goes to sleep mode in 30 seconds if it is left untouched, and it is in “navigation mode”. The device stays awake if it is left in “editing mode”. Toggling the button wakes it up, and the device starts to operate again. The device has a “power-only” USB-C connector. The MCP73831 charging controller chip is set to 200 mA charging current (Rprog = 5k), so the battery can be recharged fairly quickly. The USB-C connector makes the device up-to-date, and it allows the user to charge it according to today’s standards. I mean, no old micro USB or USB-B connectors anymore, it’s 2025!

Circuit and PCB

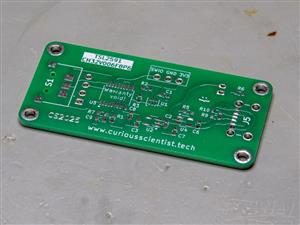

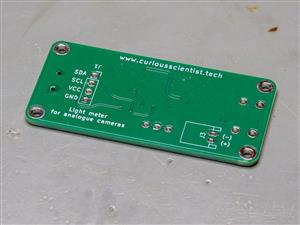

The circuit is not super difficult; it consists of a few “main sections/components” and a few smaller parts.

The first and most obvious part is the TSL2591 light meter chip. It has the basic circuit around it, which is a few pull-up resistors and a decoupling capacitor. The circuit’s other central part is the CH32V006F8P6 microcontroller. This microcontroller manages the light metering, and it also handles the calculations for determining the correct exposure values. The chip can be programmed via the SWIO pin that is made available on the top side of the PCB, together with a 3.3 V and a GND connection.

The exposure values are printed on the 0.91” OLED display on the other side of the board. The chip also measures the voltage (hence the charge status) of the lithium battery through a voltage divider and filter circuit. The output of the battery is not directly connected to the rest of the circuit, because the light meter operates at 3.3 V (it is not 5 V tolerant!). The output is regulated down to 3.3 V by an LP5907MFX-3.3 low-dropout regulator. Since the battery also has to be managed (charged) somehow, this is realised by an MCP73831T chip. The chip receives the power required for charging from a power-only USB-C connector.

Since the device needs inputs, there is a 3-way navigation switch on the other side of the PCB. This switch might be familiar to those who owned MP3 players in the old days. The switch allows the user to navigate in the menu and adjust the parameters.

Enclosure

The enclosure of the light meter circuit is fully 3D-printable. It consists of two shells that fit together nicely. The front part accommodates the PCB. The PCB sits in its “seat” tightly. This part of the enclosure has four insert nuts (M2x4x3.5) because the whole enclosure is held together with bolts. There’s also a recessed hole precisely in front of the TSL2591 sensor.

The back side of the enclosure has the four screw holes for the screws that go into the insert nuts. There is a fifth hole at the bottom of the enclosure, which is made for the 1/4” insert nut that allows the enclosure to be attached to an adapter that goes into a standard cold shoe mount. On the back side, there is a rectangular opening that matches the visible area of the 0.91” OLED display.

The enclosure is more or less optimised for size. Its main limiting factor is the size of the PCB. Probably, the PCB could have been further miniaturised, but I wanted to keep it simple and easy to be manufactured by hand. The OLED display and the battery are also limiting the size. Perhaps the battery could be replaced with a CR2032 battery, and the display could go directly on the PCB, but both these decisions make the module more difficult to use. Changing the battery would be cumbersome because it would require the user to disassemble the whole enclosure. Plus, if the display were closer to the PCB, it would make it difficult to find a place for the battery.

Assembled device and usage

The assembled device with the cold shoe adapter looks fine in my opinion. However, the mounting screw could be a bit shorter, perhaps. The light sensor sits in the centre of the enclosure; therefore, it is perfectly aligned with the optics. The display can be read easily. Both the navigator switch and the USB port are easy to access, so it is not a big trouble to use them.

The device has two modes: navigation and editing. In navigation mode, a “>” symbol indicates the current position of the selector. There are three selectable parameters: Aperture (“A”), shutter speed (“S”) and ISO. To edit any of these parameters, the user must press the navigator switch. Then the “>” symbol changes to “#”, which indicates that the parameter is selected and its value can be changed by tilting the navigator up or down. All the values are pre-programmed. The aperture values are distributed between f1.0 - f22.0 with 1/3 stop step size. The shutter speeds are distributed between 120 s - 1/8000 s. The ISO values are between 25 - 12800. The ISO values and the shutter speed values are probably a bit broader than the capability of the common film cameras, but it is better to have a bit more options than the other way around.

When the light meter is in navigation mode, the device automatically goes to sleep mode after 30 seconds of inactivity. If the device is left in editing mode, it does not go to sleep. When the button is moved, the device automatically wakes up.

The code that is needed for the project is already compiled into HEX format, and you just need the WCH-LinkUtility to upload it to your board using a programmer connected to the SWIO pin on the board.

The 3D printed enclosure requires four insert nuts with a 3.5 mm diameter, 4 mm height and M2 thread. The corresponding M2 hex screws I used are 7.3 mm long (total length), and their cap is about 3.4 mm in diameter. The 1/4" insert nut is from Ruthex and it is their "short" 1/4" threaded insert nut.

If you want to avoid the 1/4" insert nut and the cold shoe adapter, there is an alternative version for the rear shell ("Rear shell of the enclosure with built-in mount"). This part has the cold shoe mount embedded. Due to the thickness of the material and the default printing direction, I cannot guarantee that the mount will be super strong. It is recommended to pick a stronger material than PLA and handle the mount with care.

Light meter for analog cameras [CH32V006F8P6 + TSL2591]

*PCBWay community is a sharing platform. We are not responsible for any design issues and parameter issues (board thickness, surface finish, etc.) you choose.

Raspberry Pi 5 7 Inch Touch Screen IPS 1024x600 HD LCD HDMI-compatible Display for RPI 4B 3B+ OPI 5 AIDA64 PC Secondary Screen(Without Speaker)

BUY NOW- Comments(0)

- Likes(3)

-

albertscoot

Oct 17,2025

albertscoot

Oct 17,2025

-

Engineer

Oct 01,2025

Engineer

Oct 01,2025

-

Paulo Quispe

Sep 30,2025

Paulo Quispe

Sep 30,2025

- 0 USER VOTES

- YOUR VOTE 0.00 0.00

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

More by Curious Scientist

More by Curious Scientist

-

USB PD Breadboard Power Supply

In this article, I show you my new creation. It is a USB PD decoy-based breadboard power supply. All...

USB PD Breadboard Power Supply

In this article, I show you my new creation. It is a USB PD decoy-based breadboard power supply. All...

-

ADS1256 - RP2040 Custom DAQ Front Panel with GPIO

This is just a simple PCB panel that belongs to my other project which is a high-performance DAQ.A r...

ADS1256 - RP2040 Custom DAQ Front Panel with GPIO

This is just a simple PCB panel that belongs to my other project which is a high-performance DAQ.A r...

-

ADS1256 - RP2040 Custom DAQ Front Panel without GPIO

This is just a simple PCB panel that belongs to my other project which is a high-performance DAQ.A r...

ADS1256 - RP2040 Custom DAQ Front Panel without GPIO

This is just a simple PCB panel that belongs to my other project which is a high-performance DAQ.A r...

-

10th Anniversary Badge

I designed this small badge for PCBWay's 10th anniversary.I tried to make a deeper meaning to the bo...

10th Anniversary Badge

I designed this small badge for PCBWay's 10th anniversary.I tried to make a deeper meaning to the bo...

-

ADS1256 - Atmega32u4 Custom DAQ board

IntroductionIn this project, I show you two things. One is a new version (v1.2) of my custom DAQ bas...

ADS1256 - Atmega32u4 Custom DAQ board

IntroductionIn this project, I show you two things. One is a new version (v1.2) of my custom DAQ bas...

-

Debounced rotary encoder module

In this project, I show you my approach to making a rotary encoder module.One can buy different rota...

Debounced rotary encoder module

In this project, I show you my approach to making a rotary encoder module.One can buy different rota...

-

Custom ADS1256 board with ATmega32U4

I created my own ADS1256 PCB after working with this AD converter for several years. I wanted to bui...

Custom ADS1256 board with ATmega32U4

I created my own ADS1256 PCB after working with this AD converter for several years. I wanted to bui...

-

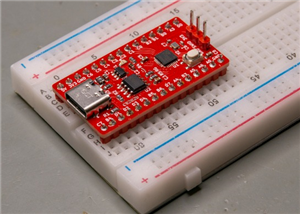

CH32V003J4M6 - Miniature microcontroller board

I wanted something small but relatively capable, and since I have some experience with the CH32V003J...

CH32V003J4M6 - Miniature microcontroller board

I wanted something small but relatively capable, and since I have some experience with the CH32V003J...

-

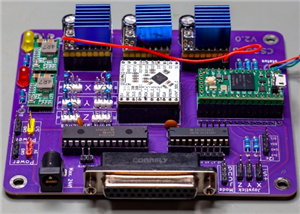

3-axis stepper motor controller with CNC pendant connectivity

In this article, I show you the updated version of my motorized microscope. In one of my older video...

3-axis stepper motor controller with CNC pendant connectivity

In this article, I show you the updated version of my motorized microscope. In one of my older video...

-

Light meter for analog cameras [CH32V006F8P6 + TSL2591]

Light meter for analog cameras [CH32V006F8P6 + TSL2591]In this article, I show you how I built my ow...

Light meter for analog cameras [CH32V006F8P6 + TSL2591]

Light meter for analog cameras [CH32V006F8P6 + TSL2591]In this article, I show you how I built my ow...

-

5-way navigator PCB

In this article, I show you a genius way of handling multiple buttons with a microcontroller. I “dis...

5-way navigator PCB

In this article, I show you a genius way of handling multiple buttons with a microcontroller. I “dis...

-

CH32V006K8U6 Development Board

IntroductionSo, I have been working with the CH32 microcontrollers and chips for a while, and I even...

CH32V006K8U6 Development Board

IntroductionSo, I have been working with the CH32 microcontrollers and chips for a while, and I even...

-

PCBWay 11-year Anniversary Badge

This visual design was created by https://www.instagram.com/guiye.perez.bongiovanni/ ; however, only...

PCBWay 11-year Anniversary Badge

This visual design was created by https://www.instagram.com/guiye.perez.bongiovanni/ ; however, only...

-

TCD1304 - STM32F401CCU6 breakout board

The recent modifications made to the circuit board design have improved its functionality and space ...

TCD1304 - STM32F401CCU6 breakout board

The recent modifications made to the circuit board design have improved its functionality and space ...

-

TCD1304 miniature PCB rev2

The redesign of the PCB involved several key changes to improve its performance and decrease its siz...

TCD1304 miniature PCB rev2

The redesign of the PCB involved several key changes to improve its performance and decrease its siz...

-

2-channel breadboard voltmeter

The project originally stems from my CH32 tutorial series. I started working with this chip not so l...

2-channel breadboard voltmeter

The project originally stems from my CH32 tutorial series. I started working with this chip not so l...

-

ADS1256 - RP2040 Custom DAQ Rear Panel

This is just a simple PCB panel that belongs to my other project which is a high-performance DAQ.A r...

ADS1256 - RP2040 Custom DAQ Rear Panel

This is just a simple PCB panel that belongs to my other project which is a high-performance DAQ.A r...

-

ADS1256 - RP2040 Custom DAQ with GPIOs

This is my (hopefully) last iteration of the ADS1256-based DAQ board. I replaced the ATmega32U4 micr...

ADS1256 - RP2040 Custom DAQ with GPIOs

This is my (hopefully) last iteration of the ADS1256-based DAQ board. I replaced the ATmega32U4 micr...

-

ARPS-2 – Arduino-Compatible Robot Project Shield for Arduino UNO

123 0 0 -

A Compact Charging Breakout Board For Waveshare ESP32-C3

609 3 4 -

AI-driven LoRa & LLM-enabled Kiosk & Food Delivery System

593 2 0 -

-

-

-

ESP32-C3 BLE Keyboard - Battery Powered with USB-C Charging

808 0 1 -

-

mammoth-3D SLM Voron Toolhead – Manual Drill & Tap Edition

732 0 1 -

-

AEL-2011 Power Supply Module

1442 0 2